Singer 645

Back in the middle of the 600 Series Touch & Sews, Singer decided that rubber-coated feed dogs would be a good idea. They would feed even the finest of fabrics without snagging or leaving marks on the fabric.

Unfortunately, Singer forgot that rubber and sewing machine oil don’t play well together and the rubber coating on the feed dogs softens and crumbles off. When that happens, fabric will not feed and the machine will not sew.

A couple of weeks ago, a friend asked me to look at a 645 that she picked up at a thrift shop. The first thing I saw was that the rubber had melted and was all out of shape.

Before investing $20 in a new feed dog, I looked at the internal gears. This series not only has a rubber feed dog, but plastic internal gears, also. All the plastic gears appeared to have been replaced because they were all black. The original gears were white and turn yellow/brown with age just before they crumble and break. Someone had spent a good deal of money having those gears replaced and I have not yet seen a black replacement gear crack or break. The machine ran quiet and smooth, so I decided it was worth the money to replace the feed dog.

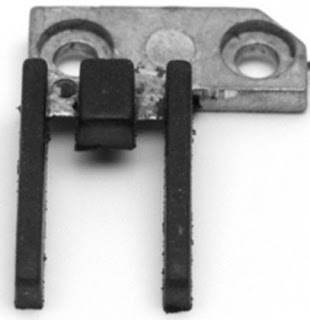

Rubber-coated feed dogs are available but there is another option. After a few years, Singer realized that rubber-coated feed dogs were a mistake and went back to metal feed dogs with teeth. Those feed dogs from later model 600 series Touch & Sews fit perfectly where the rubber feed dogs were.

Just pop off the throat plate, remove the two screws holding the feed dog and lift off the feed dog. Set the new piece in place, replace the two screws and reinstall the throat plate. Takes less than 15 minutes. The metal feed dogs are about $2 cheaper but I happened to have one in the parts bin from a machine with cracked gears that I had parted out.

After seeing this machine, I am re-thinking the plastic gear issue and might try replacing a full set myself next time I run into a 600 series Touch & Sew that needs re-gearing.

14 comments:

Ed,

Avoid the Singer Golden Touch & Sew 640 with solid state foot controller. I have one and the motor is noisier than my other Singer 600s. These models had an automatic needle threader - a tiny vacuum hose, which is supposed to pull the thread through the needle (doesn't work on mine and the clip it's attached to is broken). These machines also have an automatic needle up position. I turned it off because the machine continued to sew 5 or 6 stitches when I took my foot off the pedal.

Hi there,

I have a Singer T&S 638 that I got about a year ago at the Goodwill for $15. In the past two months I've had to replace all of the black internal gears because one broke and as I was replacing it the next one broke, then the next one, then the next one. Needless to say, the black gears DO break. Do you have any tips on how to increase their lifespan? I've replaced them with other rubber gears and I'm hoping that frequent usage and oiling of my machine will keep them from crumbling.

This is a new one on me - I have never seen a black gear fail. I had hoped that scientists had developed something better than the original white gears. Three enemies of plastic are direct sunlight, heat, and petroleum products. The gears are all internal, so sunlight should not be an issue. If the machine sits in the sun or near another heat source, keeping it cool might help. Keeping grease and oil off the plastic gears is the other thing to try. Beyond that, I guess having a spare set of gears on hand is a last resort. -Ed-

I was told the touch and sew 600 and 603E had all metal gears.

I have a Singer 1036 Creative Touch with black busted feed gears. So I always assumed the black gears, in time, were prone to failure.

The thing about buying a machine from a thrift store is...you never know how the machine was used by the prior owner. The amount of use, type of fabric sew and lubricant used on the gears, I think are key issues in determining how long the gears will last.

I've gotten several great machines from thrift stores. When it comes to non metal gears, I think you have to cross your fingers and hope for the best.

Jonathan

ok.. this is going to be completely off topic but I hope you can help me... Ijust bought a vintage necchi maximatic which does not feed the fabric properly:

It sews well when it goes in only one direction, but when I use a stitch (like stretch ones) that needs the fabric to go onwards and then backwards the machine goes over the previuous stitch (here is a picture of what I mean); is there a way to fix it?

It also does not sew backwards making buttonholes (which makes it impossible to make buttonholes!)

That's a tough one to troubleshoot from a distance! For the decorative stitch issue, check the camstack for large cracks. See my August post "Not ANOTHER Necchi" for photo of a camstack. A large crack can act as a low spot on the cam and drive the needle in a direction that was not intended. The buttonhole issue sounds like some linkage not moving as it should, either because something is broken or not properly lubricated. It's difficult to see what's going on in that model because there aren't a lot of covers to remove to gain access. -Ed

On a few Singers, the rubber feed dogs are a necessity for getting full use out of the machine. The machines are Athena 2000s and 1200s, also Touch-Tronic 2000s, 2001s, 2005s and 1200s. Certain stitch patterns won't sew properly with the metal feed dogs, like the dog and tulip patterns. It's really the user's call - if you don't use those patterns, then the metal feed dog could be the right choice.

Ah,ha! Now I understand why old SMG's call the Touch and Sew a Touch and Throw!

Too bad a company ruined its reputation over the years.

Thanks so much for this posting. I just took apart my singer golden touch and sew 640, to give it a clean up and see how it was sewing. I have owned this machine since 1970 or so. After cleaning it I remembered it wasn't sewing well last time I used it. Until I retired I did not have time to deal with it. Now I want to sew, it is an issue. After analyzing the whole thing, and lubricating it, I decided the feed dog was not feeding...I then realized it was not the old style toothed feed dog. I succeeded in getting nice stitches and tension, but I had to pull the fabric through, which I don't want to do. Your posting mentions parts to replace the feed dog. Can you give me an idea how to get these parts? I also want to mention that when I took the bottom off the machine for cleaning, it appeared that my gears are metal, but they had a white lubricant of some sort on them and it was not very lubricating. I once had the machine tuned up and I am wondering if that person put lithium grease on my gears....I just put sewing machine oil over that and the machine sounded and sewed better...but I guess I am going to have to deal with that lithium grease at some point.Thanks again for your insights.

help me out please; what are the internal gears related to the movement of the feed dogs? I replaced the two hook gears, now feed dogs will not move.

Thanks

Virginia

Thank you so much for the copies of the manuals. Its better than finding $20 in an old purse. :) Do you know of a site where I can find repair or user manuals for treadle machines?

Thanks again,

Nancy

One reason gears break is because of something binding.

Poor lubrication, a wayward thread wrapped around something, improper gear mesh, and a bearing tightened too snugly to the adjacent bushing can all cause binding. The last one happened to me, so after I replaced the gears, I made sure everything moved silky smooth before I fired up the machine.

Some lubricants can attack plastic, and sprays can have plastic safe lubes but the solvent can be damaging.

When I worked for JoAnn Fabrics, we had a large in store sewing machine center. You brought back a memory with this post. I can't even tell you how many of those feed dogs I special ordered and sold because the customer's original one was gummed up.

Post a Comment