She said there was nothing wrong with it, it just needed cleaning and oiling. The machine looks very well cared for and little used but it had a very loud clanking sound when operated. Except for that noise, the machine ran smoothly and, with the bobbin case /shuttle removed, very quietly so I was pretty certain where the noise was originating from. I opened up all the panels and oiled everything and, while doing that, found some thread wrapped around the knuckle of the thread take-up lever.

Here's where it gets goofy - AFTER I removed the thread, the machine locked up so tight that the motor wouldn't turn it over and it was difficult to rotate by hand! I looked for additional thread clogs and re-oiled evrything with no improvement. To isolate, I disconnected the connecting rod that transmits movement from the main shaft to the lower section.

This cuts the mechanism in half and tells me whether the problem is in the upper or lower section. It was in the upper section. Having exhausted all my ideas, I doused the whole upper section with Liquid Wrench and let it sit overnight. This morning, it seemed a bit looser turning by hand and, after a few revolutions, the motor took over and spun the shaft. I ran in the machine at top speed for about a minute and all the binding is gone. I have no idea where the problem was.

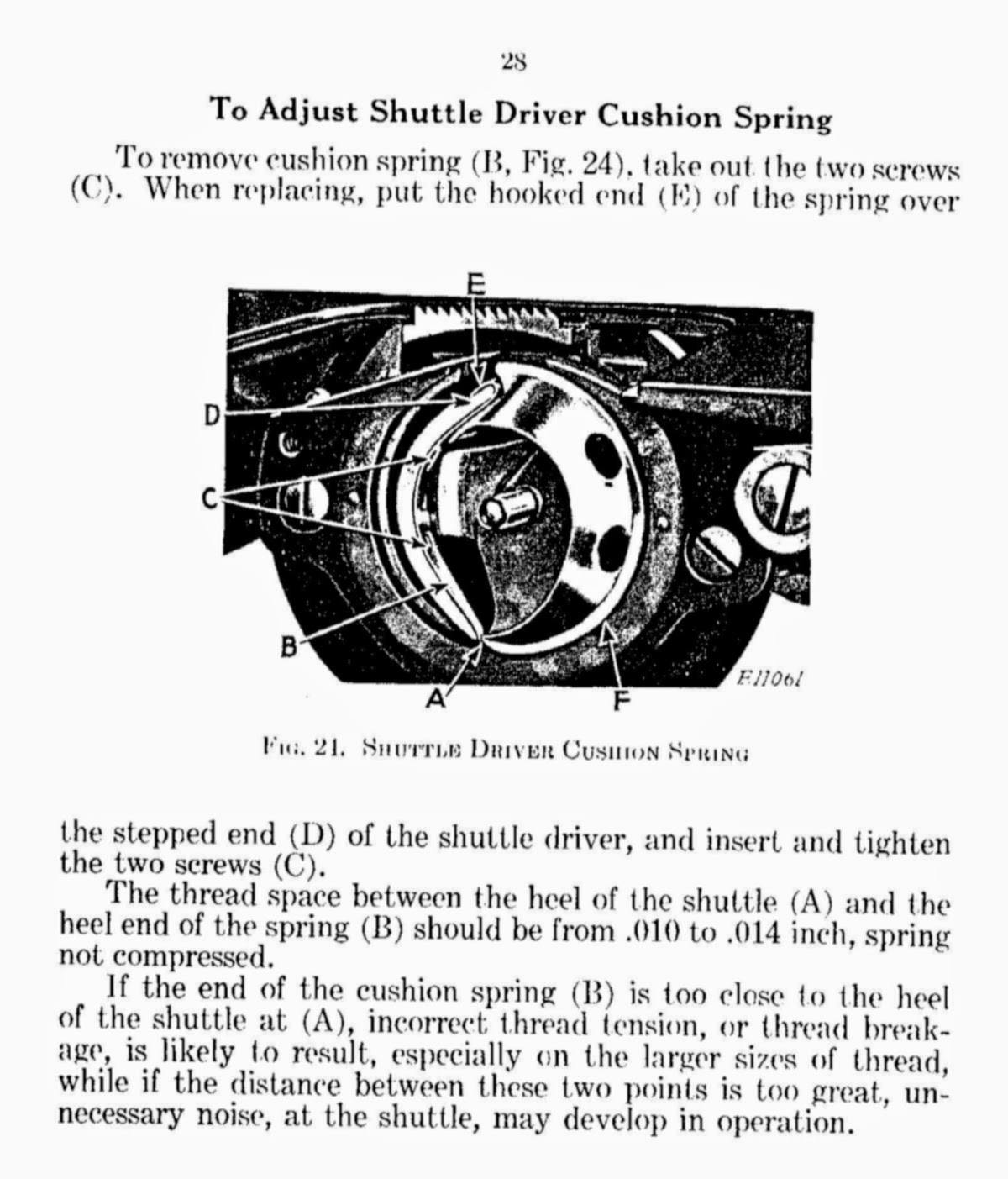

Then on to the noise in the shuttle area. The thread gap between the tip of the shuttle cushion spring and the shuttle should be just over the thickness of thread but this one was a good 1/8 inch.

That explains the noise! I went to bend the cushion spring to narrow the gap and found that there was no end - the end of the spring had broken off.

I rummaged through all my parts bins and could not find a single cushion spring. Apparently, that is something that needs replacing so seldom that I haven't kept any spares. Then I remembered the Julia I am parting out still has the cushion spring so I cannibalized it but it is too long to work in the Kenmore. Fortunately, my parts source has the springs and attaching screws in stock, so I can order replacements.

Ed

Ed's Vintage Sewing Machine Shop

Hi Ed, I have a question - not pertaining to today's post, and didn't know another way to get ahold of you. If you have any advice, I'd appreciate it.

ReplyDeleteI have a Necchi BU industrial (rare bird) which I love! The presser foot doesn't quite rest on the feed dogs when it's lowered. Do you have any idea if there is a longer shank foot that should go on this machine? Thanks! Tanya

The Necchi BU uses a standard high shank foot same as 99% of industrial machines. If your foot is not resting on the feed dog, it could be because you have a low shank foot or the presser bar height needs adjusting or the presser bar is sticking and needs to be oiled. -Ed

ReplyDeleteThanks, Ed. Appreciate the advice. I'm betting on adjusting the presser bar height. --Tanya

ReplyDeleteI recently purchased a 158.19142 which is in relatively good condition as far as I can tell right now. It does need a new lower drive belt, though. I have not been able to find a service manual for it so I'm not sure how to go about doing so. Do you have any idea where I can find a manual?

ReplyDeleteGreetings Ed, I feel like a super detective in finding your information on the Sears Kenmore model 1720. I received the same model for my 17th birthday almost 42 years ago. I have essentially taken very good care of it and it has served me well over the years. I am looking to replace the small motor belt. I ordered both large and small but the small one has been on back order for several months. I stripped my belt trying to repair a backpack (much too heavy gauge) on Thanksgiving day. Any leads on purchasing a new one would be helpful ~ Thank you Lisa

ReplyDelete